-

Table of Contents

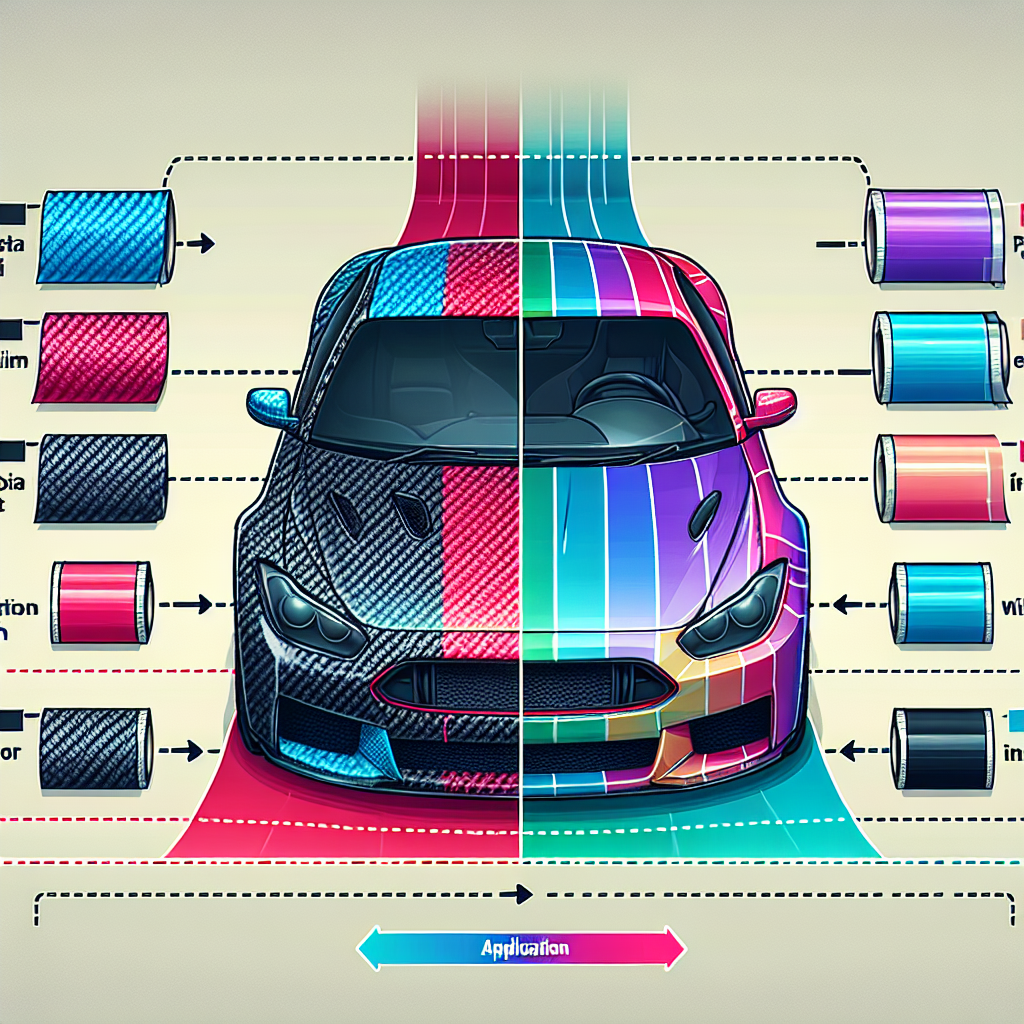

“Car Wrap, PPF, or Window Tint: Master the Order for Ultimate Protection and Style!”

When it comes to enhancing and protecting your vehicle’s appearance, car enthusiasts often consider three popular options: car wraps, paint protection film (PPF), and window tint. Each of these applications serves a unique purpose, from aesthetic customization to safeguarding the vehicle’s surfaces from damage and improving privacy. However, the order in which these treatments are applied can significantly impact their effectiveness and longevity. Understanding the differences between car wraps, PPF, and window tint, as well as the best practices for their application sequence, is essential for achieving optimal results and ensuring your vehicle looks its best while remaining protected.

Car Wrap Application Process: Best Practices

When considering the application of a car wrap, it is essential to understand the best practices that ensure a successful and long-lasting finish. The process begins with thorough preparation, which is crucial for achieving optimal adhesion and appearance. First and foremost, the vehicle’s surface must be meticulously cleaned to remove any dirt, grease, or wax. This step is vital because any contaminants left on the surface can lead to imperfections in the wrap, such as bubbles or peeling. Using a high-quality automotive soap followed by a thorough rinse and drying with a microfiber cloth can help achieve a pristine surface.

Once the vehicle is clean, it is advisable to inspect the paint for any imperfections, such as scratches or chips. Addressing these issues before applying the wrap is important, as they can become more pronounced once the wrap is in place. If necessary, minor repairs can be made using touch-up paint or a professional detailing service. After ensuring the surface is smooth and free of defects, the next step involves measuring and cutting the vinyl wrap. Precision is key during this phase, as accurate measurements will prevent waste and ensure that the wrap fits the vehicle perfectly.

As the application process begins, it is essential to work in a controlled environment. Ideally, the application should take place in a clean, dust-free area with a stable temperature. Extreme temperatures can affect the adhesive properties of the vinyl, so maintaining a moderate climate is crucial. Additionally, using tools such as a squeegee and a heat gun can facilitate a smoother application. The squeegee helps to eliminate air bubbles and ensure that the wrap adheres evenly, while the heat gun can be used to soften the vinyl, making it more pliable for curves and contours.

During the application, it is important to start from one end of the panel and work methodically to the other, applying the wrap in sections. This technique not only helps in managing the material but also allows for better control over the placement and tension of the vinyl. As the wrap is applied, it is advisable to periodically check for any air bubbles or wrinkles, as these can compromise the overall appearance and durability of the wrap. If any imperfections are detected, they should be addressed immediately, either by lifting the vinyl and reapplying or by using the heat gun to smooth out the area.

After the wrap has been fully applied, the final step involves trimming the excess vinyl around the edges of the panels. This requires a steady hand and a sharp blade to ensure clean lines and prevent any lifting at the edges. Once trimmed, it is beneficial to apply a post-heat treatment to the edges, which helps to secure the wrap and enhance its longevity. Finally, allowing the wrap to cure for a specified period before exposing it to harsh conditions is advisable. This curing time can vary depending on the manufacturer’s recommendations, but it is generally a good practice to avoid washing or waxing the vehicle for at least a week after application.

In conclusion, the car wrap application process demands careful attention to detail and adherence to best practices. From thorough cleaning and surface preparation to precise application techniques and post-application care, each step plays a critical role in achieving a professional finish. By following these guidelines, vehicle owners can enjoy the aesthetic and protective benefits of a high-quality car wrap for years to come.

PPF Installation: Timing and Techniques

When considering the protection and enhancement of a vehicle’s exterior, the timing and techniques of applying Paint Protection Film (PPF) are crucial elements that can significantly influence the overall outcome. PPF serves as a transparent barrier that shields the vehicle’s paint from scratches, chips, and environmental contaminants. Therefore, understanding the optimal timing for installation is essential for achieving the best results.

To begin with, it is important to note that the condition of the vehicle’s paint plays a pivotal role in determining when to apply PPF. Ideally, the surface should be free of imperfections such as swirl marks, scratches, or oxidation. Consequently, a thorough paint correction process is often recommended prior to PPF installation. This step not only enhances the aesthetic appeal of the vehicle but also ensures that the film adheres properly to a smooth, clean surface. Therefore, scheduling a paint correction before the PPF application is a wise decision that can lead to a more satisfactory outcome.

Moreover, the timing of the installation itself is another critical factor. PPF should ideally be applied in a controlled environment, such as a professional installation facility, where temperature and humidity can be regulated. This is because extreme weather conditions can adversely affect the adhesive properties of the film. For instance, applying PPF in high humidity can lead to moisture being trapped beneath the film, which may result in bubbles or peeling over time. Conversely, applying it in excessively dry conditions can cause the adhesive to cure too quickly, compromising the bond between the film and the vehicle’s surface. Therefore, selecting a day with moderate weather conditions is advisable for optimal results.

In addition to timing, the techniques employed during the installation process are equally important. Professional installers typically utilize a combination of methods, including wet and dry application techniques, to ensure a seamless finish. The wet application method involves using a solution to lubricate the surface, allowing for easier positioning and adjustment of the film before it adheres. This technique is particularly beneficial for larger panels, as it minimizes the risk of misalignment and allows for repositioning if necessary. On the other hand, the dry application method is often used for smaller areas or intricate designs, where precision is paramount. Understanding these techniques and their appropriate applications can significantly enhance the effectiveness of the PPF installation.

Furthermore, it is essential to consider the curing time after the installation of PPF. While the film may appear to be securely adhered immediately after application, it requires a certain period to fully cure and bond with the vehicle’s surface. During this time, it is advisable to avoid exposing the vehicle to harsh conditions, such as direct sunlight or heavy rain, as these factors can interfere with the curing process. Typically, a curing period of at least 24 to 48 hours is recommended before subjecting the vehicle to regular use.

In conclusion, the successful installation of Paint Protection Film hinges on careful consideration of timing and techniques. By ensuring that the vehicle’s paint is in optimal condition, selecting appropriate weather conditions for application, employing effective installation methods, and allowing sufficient curing time, vehicle owners can maximize the benefits of PPF. Ultimately, these steps not only enhance the vehicle’s appearance but also provide long-lasting protection against the rigors of daily driving.

Window Tinting: Order of Application and Benefits

When considering the enhancement and protection of a vehicle’s exterior, the order of application for various treatments such as window tinting, car wraps, and paint protection film (PPF) is crucial. Among these, window tinting often serves as the first line of defense against harmful UV rays and excessive heat, while also providing privacy and aesthetic appeal. Understanding the benefits of window tinting and its optimal application order can significantly influence the overall effectiveness of these treatments.

Window tinting involves applying a thin film to the interior side of a vehicle’s windows. This film is designed to reduce glare, block harmful UV rays, and maintain a comfortable temperature within the vehicle. One of the primary benefits of window tinting is its ability to protect the vehicle’s interior from sun damage, which can lead to fading and deterioration of upholstery and dashboard materials. Additionally, window tinting enhances privacy for passengers and belongings, making it a popular choice among vehicle owners.

When considering the application order, it is essential to apply window tint before any other exterior treatments, such as car wraps or PPF. This sequence is important for several reasons. First, applying window tint first allows for a clean and unobstructed surface for the film to adhere to, ensuring optimal performance and longevity. If a car wrap or PPF is applied first, the edges of these materials may interfere with the tint application, potentially leading to peeling or bubbling over time. Furthermore, window tinting requires a specific curing process, which can be compromised if other films are applied beforehand.

Moreover, applying window tint first can enhance the overall aesthetic of the vehicle. Once the tint is in place, the contrast between the tinted windows and the exterior wrap or PPF can create a more cohesive and polished look. This visual harmony is particularly appealing for those who wish to make a statement with their vehicle’s appearance. Additionally, the tinted windows can help to mask any imperfections in the glass, further contributing to a sleek and refined exterior.

In terms of functionality, window tinting also plays a significant role in the performance of other treatments. For instance, by reducing the amount of heat entering the vehicle, window tinting can help to alleviate the strain on the air conditioning system, leading to improved fuel efficiency. This benefit is particularly relevant in regions with high temperatures, where the combination of window tint and PPF can work synergistically to protect the vehicle’s paint from thermal expansion and contraction.

In conclusion, the order of application for window tinting, car wraps, and PPF is a critical consideration for vehicle owners seeking to enhance both the appearance and protection of their cars. By applying window tint first, one can ensure optimal adhesion, aesthetic appeal, and functional benefits that contribute to the longevity of the vehicle’s interior and exterior. Ultimately, understanding the unique advantages of window tinting and its role in the overall treatment process can lead to a more informed decision, resulting in a vehicle that not only looks great but also stands the test of time.

Q&A

1. **Question:** What should be applied first: car wrap, PPF, or window tint?

**Answer:** It is recommended to apply PPF first, followed by car wrap, and then window tint.

2. **Question:** Why is PPF applied before car wrap?

**Answer:** PPF is applied first to protect the vehicle’s paint from scratches and damage, providing a smooth surface for the car wrap.

3. **Question:** What is the reason for applying window tint last?

**Answer:** Window tint is applied last to ensure that it adheres properly without being affected by the installation of PPF or car wrap.In conclusion, when considering the application order of car wrap, paint protection film (PPF), and window tint, it is generally recommended to apply PPF first, followed by car wrap, and then window tint. This sequence ensures that the paint is protected before any decorative elements are added, and the tint is applied last to maintain its integrity and effectiveness.